Join the Pipe

Braskem has partnered up with Join the Pipe to distribute sustainable and reusable water bottles made with I’m Green polyethylene in Europe, Africa and the U.S. The income generated from the product will be intended for over 300 social projects in developing countries, most of them in Africa and Asia.

Bottle Up

Bottle Up and Braskem partnered up to deliver reusable water bottles made from I’m Green polyethylene. This way, Bottle Up not only transitions the product bottles from being single-use to multi-use, but they also significantly reduce the carbon footprint of the product. Bottle Up bottles are sold at popular locations like Albert Heijn, Jumbo, WHSmith, Stach, HEMA, Holland&Barret, BP, Coop and more.

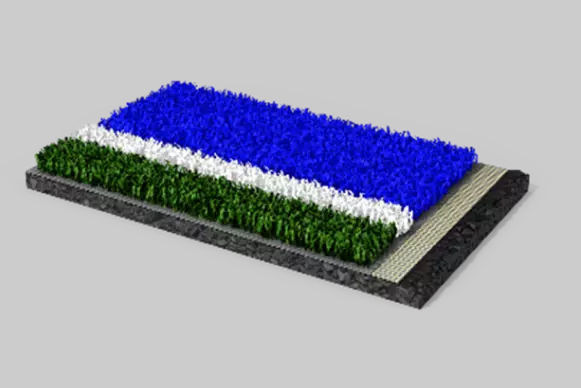

Hockey fields

Braskem and Polytan provide I’m Green polyethylene for the hockey fields for the Olympic Games in Tokyo in 2020 and the 2022 hockey World Cups. Using this material for the artificial turf production delivers the same turf quality, whilst making a positive impact on hockey fields’ carbon footprint.

AllBirds

Allbirds uses Braskem’s renewable bio-based EVA resin in its Sugar footwear line. With characteristics such as flexibility, lightness and resistance, the resin combines comfort, design and sustainability and helps to reduce greenhouse gases in the air by capturing and storing CO2 during its production process.

Roberts Mart

Roberts Mart produces printed flexible packaging used to store bedding items for the John Cotton Group Ltd. They are using Braskem’s I’m green™ polyethylene derived from sugar cane, making a valuable contribution to the reduction of greenhouse gas emissions. The bio-based material proves to be of the same standards in performance and visual quality as fossil-fuel based bags, is recyclable through the same processes and thus is a sustainable alternative.

WeNew

WeNew is Braskem’s circular ecosystem, which is comprised of products, education, technology and circular design, consolidating all of the company’s actions focused on recycling and the circular economy under a single umbrella.

Valoren

In 2022, Braskem partnered with Valoren, a company specialized in developing and operating technologies for waste transformation, to construct a recycling line and expand our portfolio of post-consumer resins. The partnership constructed a recycling unit with the capacity to transform 250 million packages into 14 thousand tons of post-consumption recycled resins per year.

Nexus Circular

Braskem produces circular polypropylene (PP) utilizing Nexus Circular’s commercial-scale chemical recycling technology. This chemical recycling facility converts difficult-to-recycle plastics, such as plastic films discarded in landfills, into circular raw materials for the supply of circular feedstocks.