Mass balance: learn more about the method that allows you to expand the offer of more sustainable products

The elimination of plastic waste and the battle against climate change are two major global challenges and are among Braskem's primary commitments towards sustainable development.

To make progress on these issues, Braskem has been dedicating its efforts on numerous levels, most of them solidified in an expansion of its sustainable global portfolio in both resins and chemicals, with a wide range of applications in all sectors of the economy.

"We want to continue addressing the demands of the market and make people's lives better through an increasingly sustainable portfolio of solutions. Pier Pesce, business development manager for the Circular Economy in South America, explains, "The mass balance method is an important way for us to move forward in this direction, in a certified and safe way, strengthening the circular economy."

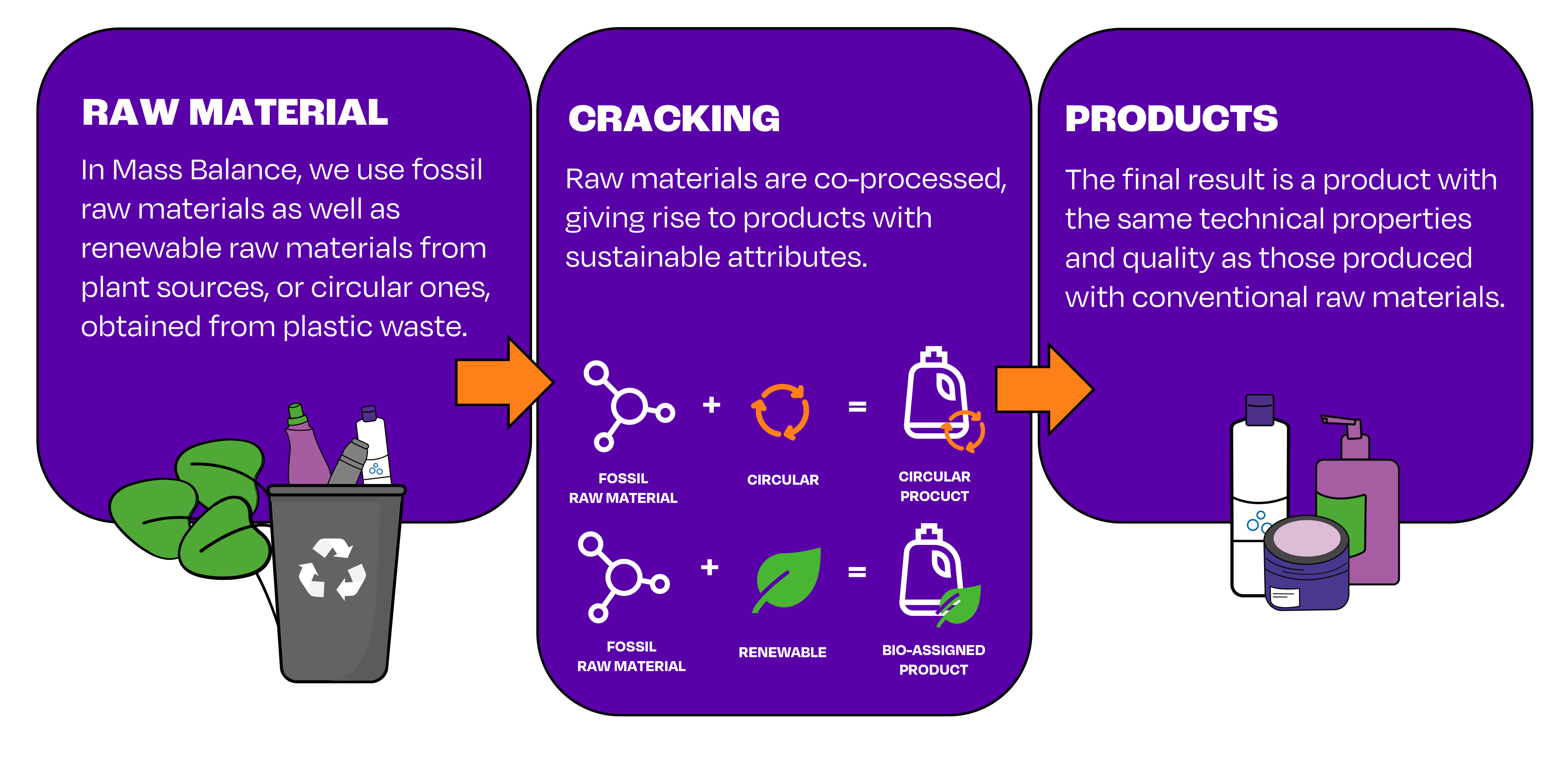

What is mass balance?

The application of the method known as mass balance allows the quantity and sustainability characteristics of renewable or circular materials to be monitored which, combined with fossil raw materials during the production process, result in high quality and performance solutions.

The method also makes it possible to allocate the amount of sustainable raw material from a predefined process, proving its lower environmental impact.

"We are talking about a co-processing of raw materials, without the need to separate the inputs during production and with the maintenance of the same characteristics of products developed exclusively with fossil raw materials, that is, products of conventional origin with a high performance," Pier states.

"This opens many perspectives for the use of circular or renewable raw materials, plus creates conditions for brands to communicate their sustainable attributes, generating more demand, which in turn is essential for the circular economy to continue expanding," he adds.

At Braskem, the units are based on the process certified by ISCC Plus (International Sustainability and Carbon Certification) for the use of renewable or circular raw materials, ensuring the reliability and transparency of the mass balance.

Circular products: chemical recycling and the concept of mass balance

Recycling is a key part of the transition to a circular economy and there are two key methods Braskem has been investing in: mechanical recycling, the main way waste is currently recycled, and chemical recycling, a process that expands the possibilities of recycling more complex and difficult-to-address plastic waste via mechanical recycling.

In chemical recycling, the physicochemical properties of waste are altered through a heating process, which breaks down post-consumer plastic molecules, giving rise to recycled raw materials such as pyrolysis oil, also known as circular oil.

"Mass balance is essential in ensuring that this oil, which is the result of the chemical recycling process of plastics, can be used in the manufacture of new circular chemicals," Pier explains.

In order to make a growing supply of products with recycled content available to the market, Braskem has been continuously expanding its access to circular raw material from the chemical recycling process.

In the United States and Europe, respectively, we have partnerships such as the one signed in 2022 with Nexus Circular , in 2023 with Vitol , in the same year, and more recently, at the beginning of 2024, with Shell which, in addition to supplying Braskem with bio-circular propylene, has also started to supply bio-attributed propylene (produced from renewable sources).

Braskem is also working on the development of an innovative technology for chemical recycling , whose differential is the use of an exclusive catalyst that makes efficient heat management during the production of the circular raw material, reducing the need for external energy sources and, consequently, CO2 emissions, which will make the process even more sustainable as a whole.

Bio-attributed products: renewable sources and the concept of mass balance

In the field of renewable raw materials, there are also advancements and partnerships.

Braskem signed a partnership in 2023 with Indorama Ventures IOD - Oxiteno to supply bio-circular ethylene. It is the first bio-assigned chemical from Braskem, meaning it is ethylene produced by the co-processing of renewable and fossil sources based on the concept of mass balance. Braskem's bio-assigned ethylene will be used by Oxiteno to create new sustainable solutions.

The partnership between Braskem and Oxiteno represents an unprecedented advance in the Brazilian chemical industry and is in line with the sustainable development goals of both companies. "This initiative is expected to define new paths in our sector," says Marlisa Reche, Braskem's Chemicals - Olefins and Aromatics Business director.

In the United States, the previously mentioned partnership between Braskem and Shell also involves the supply of bio-assigned propylene, ensuring the growing availability of sustainable resins in Braskem's global portfolio.

Learn about the mass balance method:

To find out more about Braskem's commitments to sustainable development, click here .