Final Closure of Rock Salt Extraction

In May 2019, Braskem announced the preventive shutdown of rock salt extraction. Consequently, production at the Maceió plant was also halted, which partially impacted the operation of the Marechal Deodoro PVC plant as well as the Camaçari Complex in the State of Bahia. Even after the shutdown, Braskem committed not to make layoffs and engaged the plant's personnel in maintenance and professional training activities.

In February 2021, after studying alternatives for the supply of raw materials, the plant resumed operations with salt purchased from Chilean licensed deposits. The operations at the two plants rely on the support of over 60 companies, and approximately 12,000 people are employed there – among which 750 are direct employees of Braskem, and the other 3,300 are outsourced.

In November 2019, Braskem presented to the Brazilian National Mining Agency (ANM) and other authorities measures for the termination of rock salt extraction activities, as well as the closing and backfilling of its wells in Maceió with a focus on the safety of people above all. This action is part of the initiatives proposed in the company's ongoing discussions with the regulatory authority.

Among the efforts, a Protected Area was initially created around 15 rock salt wells with the relocation of people and the eviction of about 500 properties. Currently, added to the Protected Area are about 14,400 properties being vacated. Under the agreement, residents, local traders, and entrepreneurs with properties in these regions are assisted by the Financial Compensation and Relocation Support Program. .

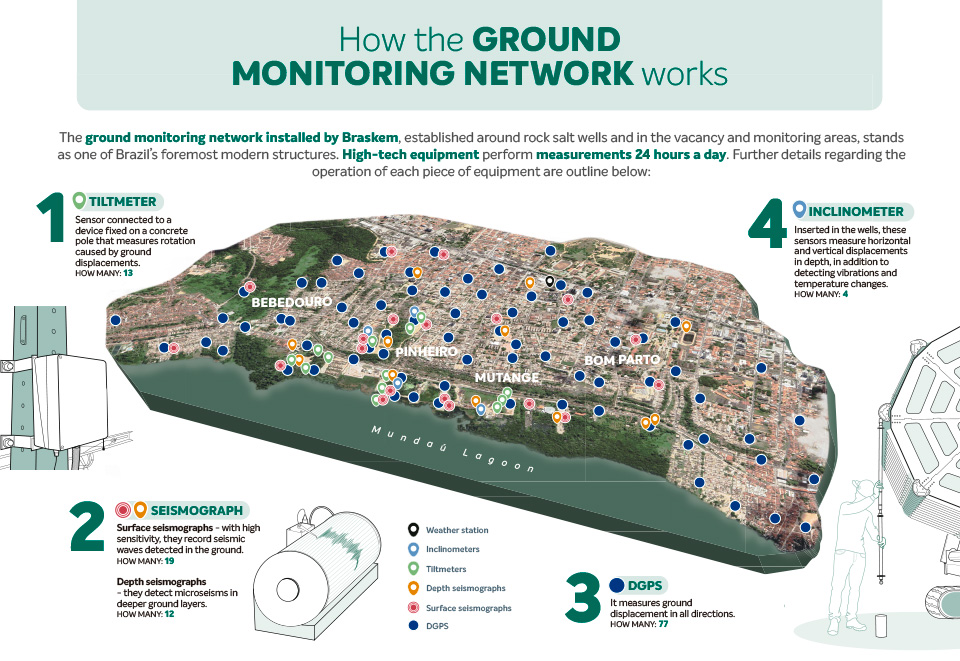

Braskem supplied the necessary resources and the entire planning for accomplishing the said efforts in concert with the Civil Defense and other authorities. All measurements and actions were – and still are – based on the technical work of the Institute of Geomechanics of Leipzig (IFG), Germany. An international benchmark for this niche, IFG has been conducting studies to understand the status of all rock salt wells.

Rock Salt Extraction and Name Change

The rock salt deposit in Alagoas, found at depths of over 850 meters and with a total reserve estimated at three billion tons, was discovered in 1943 as part of a mineral exploration in search of oil. Still, it was only in 1970 that a presidential decree authorized the start of extraction.

In 1976, the then-company Salgema began extraction for dichloroethane production at the Pontal da Barra plant. In 1995, its management changed, and the petrochemical company was renamed Trikem in 1996. In 2002, after the merger of Trikem with other companies in the industry, Braskem was created, which maintained the operation in the State of Alagoas.

During the activities of Salgema and Braskem in Maceió, 35 rock salt wells were drilled in the region near the Mundaú Lagoon, always under the supervision of the competent authorities. Every year, Braskem submits to the Brazilian National Mining Agency (ANM) a report on its activities, as provided by law, and keeps the operational licenses of its wells updated. Additionally, the regulatory authority carries out inspections from time to time. Before the establishment of the ANM in 2017, the inspection was the responsibility of the Brazilian National Department of Mineral Research (DNPM).

In turn, environmental licensing for the operation of rock salt wells and brine pipeline – which carries raw material to the plant – is warranted by the Environmental Institute (IMA) of the State of Alagoas. The IMA monitors compliance with all restrictions provided for in the license. In addition to the periodic renewals of the environmental license, Braskem also annually sends technical monitoring reports of rock salt wells to IMA.

In 2012, on its tenth anniversary, Braskem launched its PVC plant in the Industrial Complex of Marechal Deodoro, a city neighboring Maceió, becoming the largest producer of this polymer in the Americas. Such a production unit was designed to use the dichloroethane produced at the Pontal da Barra plant as raw material, sent by piping to the new plant. Dichloroethane, like soda, is produced from salt.