Braskem

-

English

- Languages

- Portuguese

- English

- Spanish

- Worldwide Sites

- United States

- Mexico

- Europe & Asia

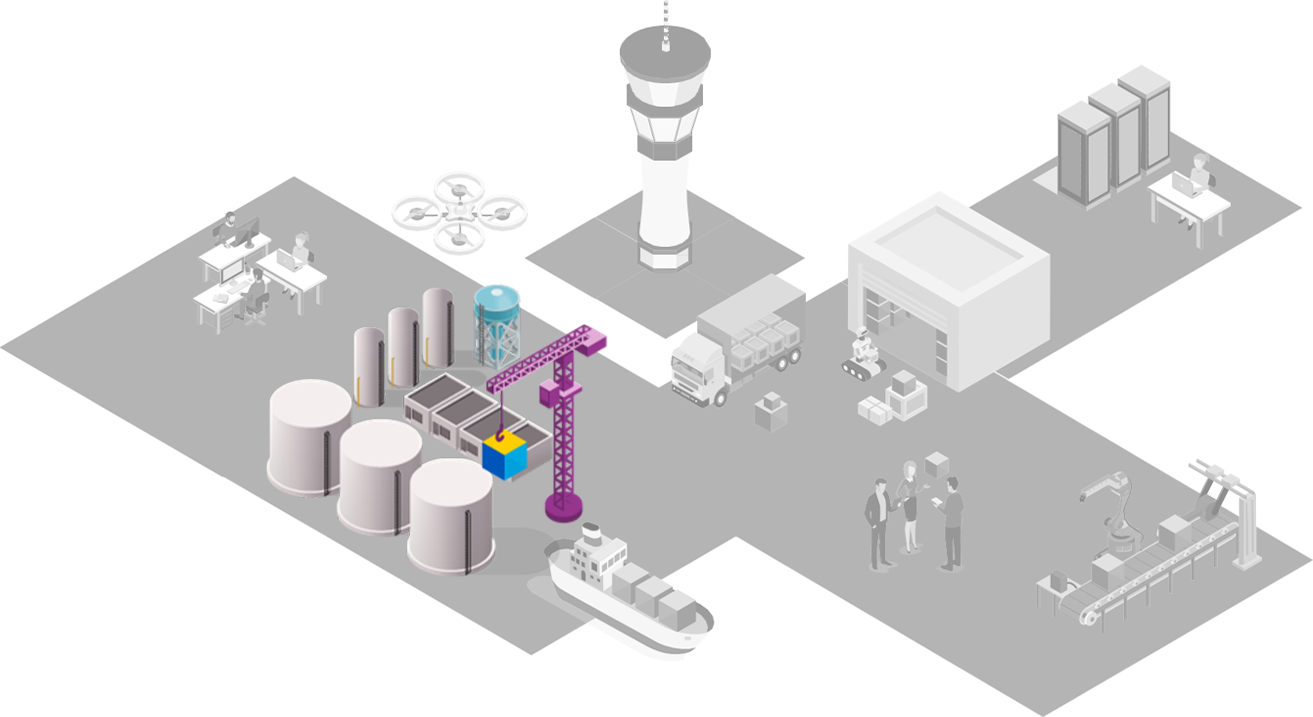

Braskem’s comprehensive roadmap for global digital transformation is guiding our implementation of innovative initiatives across the company. In today’s rapidly changing business environment, we’re evolving to serve our clients in extraordinary ways.

Our investment in exciting digital technologies -- such as advanced analytics, automation, artificial intelligence, and IoT applications – ensures that we will continue to provide the highest quality products and services and remain a leader in the petrochemical industry for decades to come. These leading-edge technologies enable us to work more efficiently and sustainably, anticipate and meet our clients’ needs, and produce chemicals and plastics that improve people’s lives.

Over 50 digital initiatives across all areas of Braskem, from manufacturing and maintenance to sales and supply chain, are transforming how our Team Members work and making us better partners to our clients. With the potential to reshape the entire industry, we’re exploring new opportunities to expand our business through three new internally incubated ventures.

Operations

Predictive maintenance supported by Advanced Analytics:

This initiative will use Advanced Analytics to optimize asset maintenance, reducing unplanned downtime and maintenance costs. Multiple sensors in the equipment will transmit data (e.g., pipe thickness, vibration) to a centralized system. The data collected will then be analyzed to derive meaningful insights. By applying an Analytical model to database, we will be able to learn from it and predict likelihood of breakdown. The analysis will reveal necessary actions, such as parameters adjustment, need for maintenance, part replacement etc.

This initiative has already successfully launched MVPs in several equipment families in Brazil, Mexico, and the U.S. involving multiple teams – Industrial, Maintenance, Digital, Automation, and IT. Its industrialization is planned for 2019.

Operations

Process Control and Optimization:

Accelerate brainstorming, root cause analysis and process optimization through a tool that leverages data exploration and visualization. The tool will enable process engineers to quickly identify process deviations and act to correct them.

Operations

Quality Control:

Using two different types of technology – sensors and advanced analytics – Braskem will be able to identify patterns and preempt quality issues to allow for corrective actions in-line in real-time. The initiative will allow us to minimize off-spec products; reduce waste; reduce fixed costs in the labs; and give our Lab Technicians time to focus on more strategic tasks.

This initiative relies on two different approaches, both validated through MVPs: 1) Data-centric approach, implemented at Markus Hook and Rio Grande do Sul, allows us to predict product quality using data collected from the process; 2) Sensor-centric approach, rolled out at Neal and Markus Hook, allows us to evaluate our polymers by interpreting signals captured through lasers. Both approaches have industrialization planned for 2019.

Supply Chain

Demand Forecast:

Braskem is working on an initiative to use advanced analytics to get greater insight into our Clients’ needs and all the different drivers involved in product demand. This will reduce error in allocating demand, improve delivery and inventory management, and reduce the burden of forecasting on our sales team, with improvements of as much as 30% in accuracy levels.

Supply Chain

Capacity forecasting and allocation:

Braskem will use Advanced Analytics to take inventory management to the next level. The tool will forecast each asset’s capacity in a probabilistic fashion to help us understand their individual capacity and how they contribute to the overall production. This will allow us to optimizing the placement of our inventory and set the stage for better decision making.

Supply Chain

Production scheduling supported by Advanced Analytics:

A robust and automatized tool will help Braskem optimize its production scheduling process, improving the current simulation-based model. We will use Advanced Algorithms to identify patterns in Client orders to reach the optimal combination of timing, grade, and volume needed for each location. The initiative will help Braskem reduce logistic costs and manage inventory.

Supply Chain

Control Tower as a central information platform:

The Control Tower will be a centralized center with end-to-end visibility of our Supply Chain and Operation performance. The Tower will provide our teams the KPIs they need and give them the ability to make decisions in real time based on an advanced scenario-modelling tool that uses Artificial Intelligence and Big Data. The end goal is to support decision-making and help lower Supply and Logistics costs.

Supply Chain

Shipping freight forecasting model:

This initiative will introduce to Braskem an Advanced Analytics model that considers different variables, such as supply and demand around the world, to support us make decisions related to contracting ship freight. The tool will help us map maritime transport flow globally, reduce logistic costs, and optimize our decision-making.

Supply Chain

Track-trace system for finished products:

By attaching devices such as RFID and GPS to our product, Braskem will be able to monitor its location in real time, both inside our warehouses and during distribution. This initiative will help us with in several processes, from inventory management, shipping, and demand forecasting, to marketing intelligence.

Supply Chain

Feedstock Portfolio Management:

An Advanced Analytics tool will give us important insight into the market, such as future prices and storage levels, which we will be able to leverage when developing our feedstock commercial strategies (i.e. hedging alternatives and anticipated feedstock contracts).

Procurement

E-procurement:

A platform where Braskem’s Procurement team and our vendors will interact to place requests, make updates, monitor contract progress, etc. increasing compliance and productivity.

Marketing and Sales

Dynamic Pricing:

Braskem will combine Advanced Analytics and Artificial Intelligence to tailor pricing based on product, Client profile, geolocation and requested delivery date.

Marketing and Sales

Market Intellingence 4.0:

Use of geospatial technology for primary market intelligence information (Orbital Insight, Genscape, etc).

Marketing and Sales

Order-to-cash process detail:

Braskem will boost our Back Office work by applying Big Data and Advanced Analytics to improve our credit analysis, support decision-making, and improve our ability to predict late payments.

Our Digital Center is leading this effort by fostering a digital workplace culture where Team Members are empowered to learn and innovate, and where they receive the tools and build the skills they need to prepare for the positive changes underway at Braskem. The Digital Center is also connected to the startup ecosystem and collaborates with partners that have solutions to address our internal challenges as well as those of the petrochemicals industry at large.

Click on each initiative to find out more

Among the many exciting digital initiatives we’re investing in, two ongoing projects exemplify well Braskem’s commitment to our clients and to remaining a leader in the petrochemical industry: Quality Control and Predictive Maintenance.

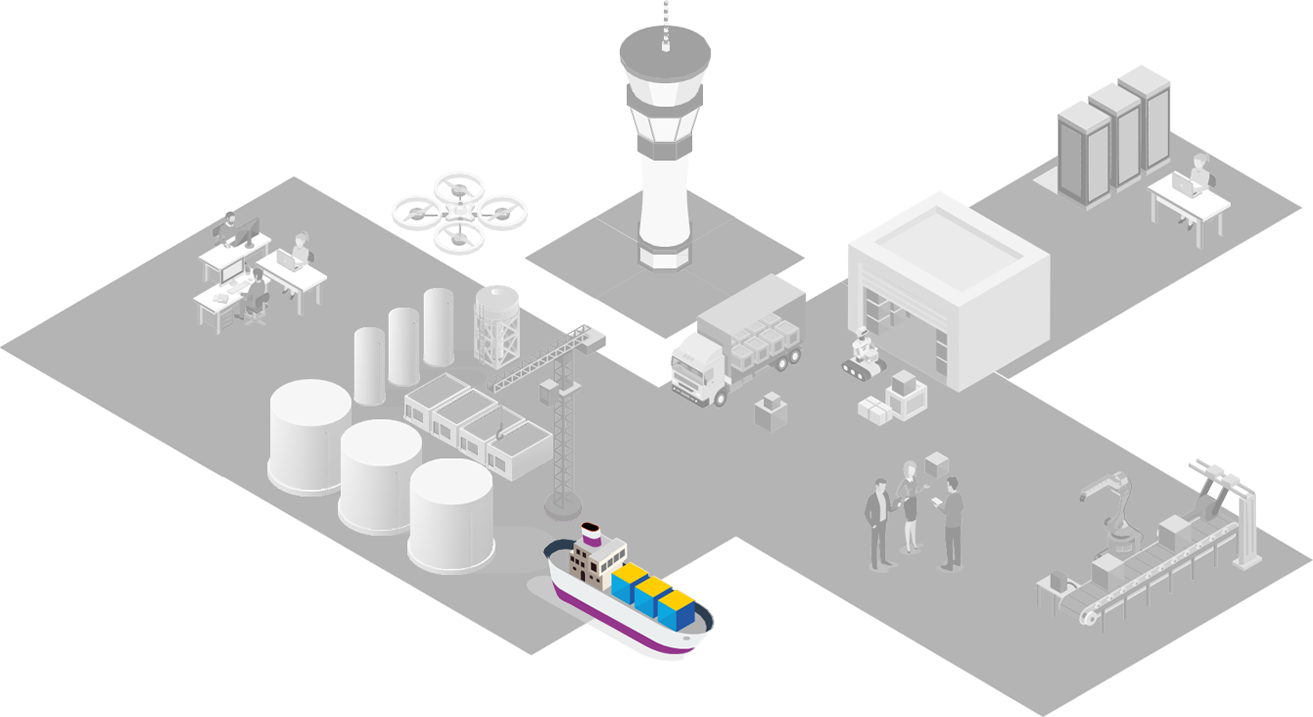

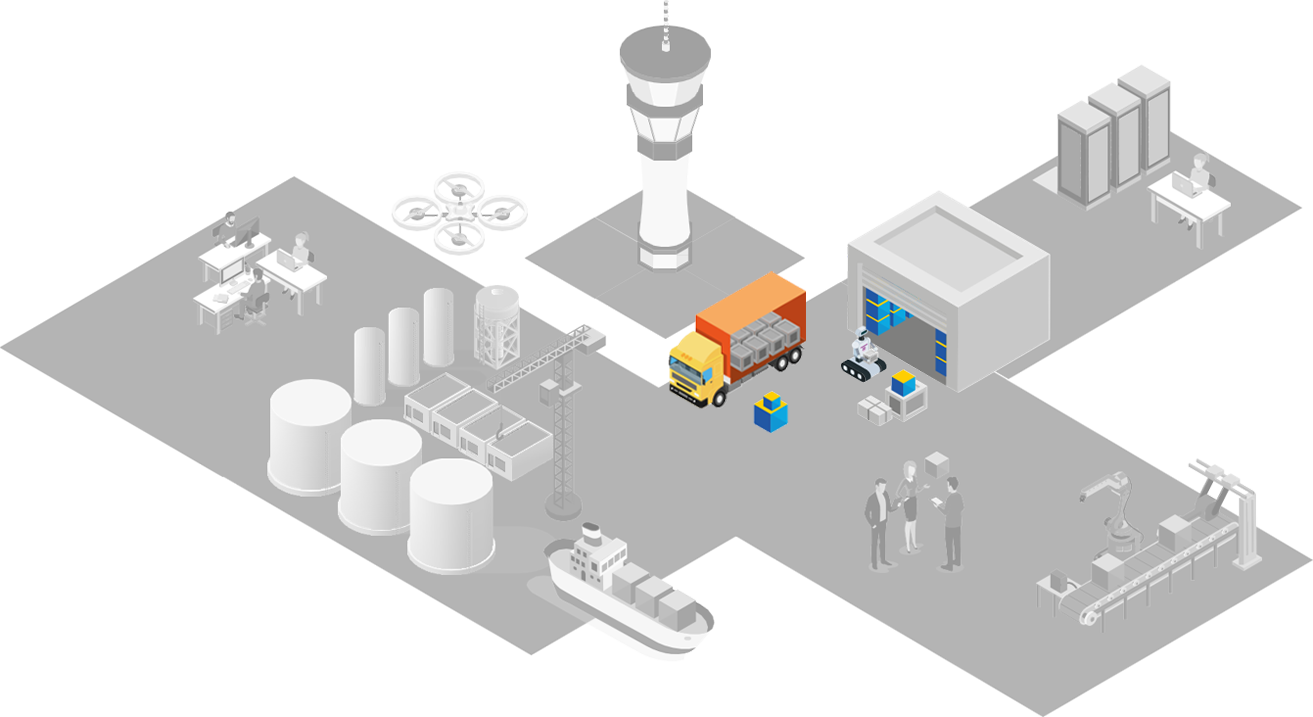

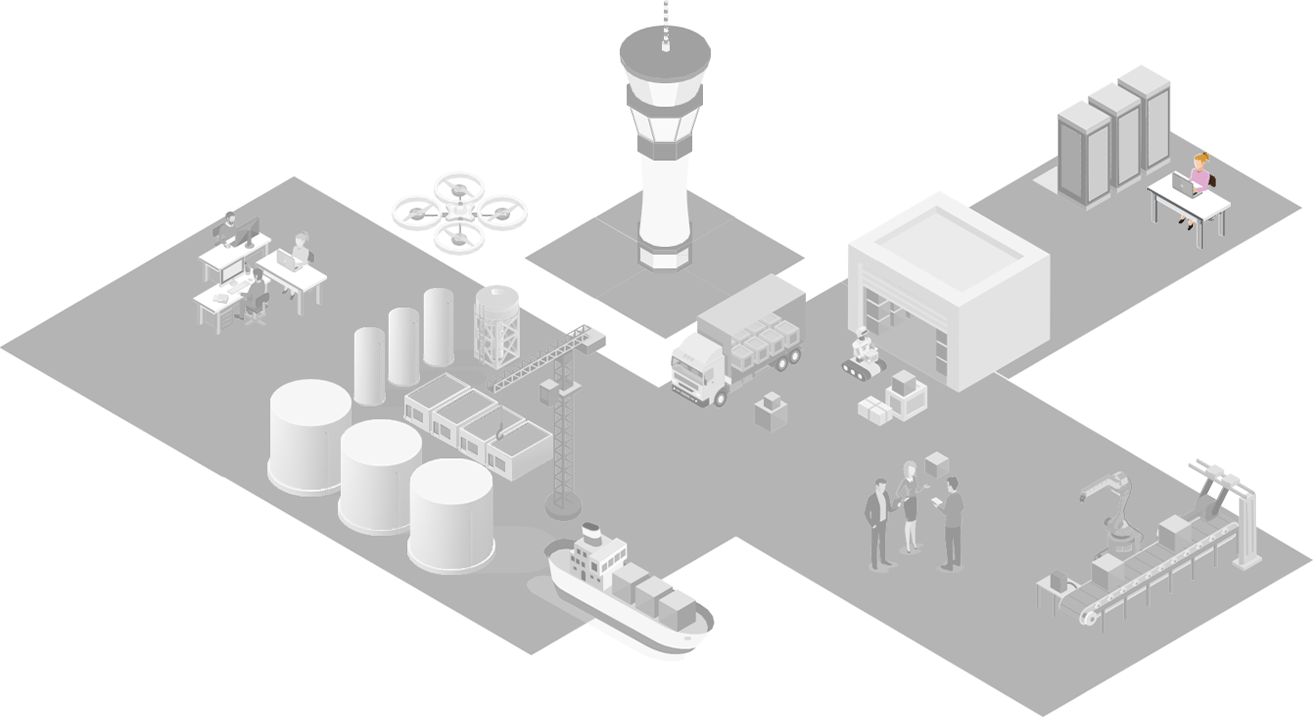

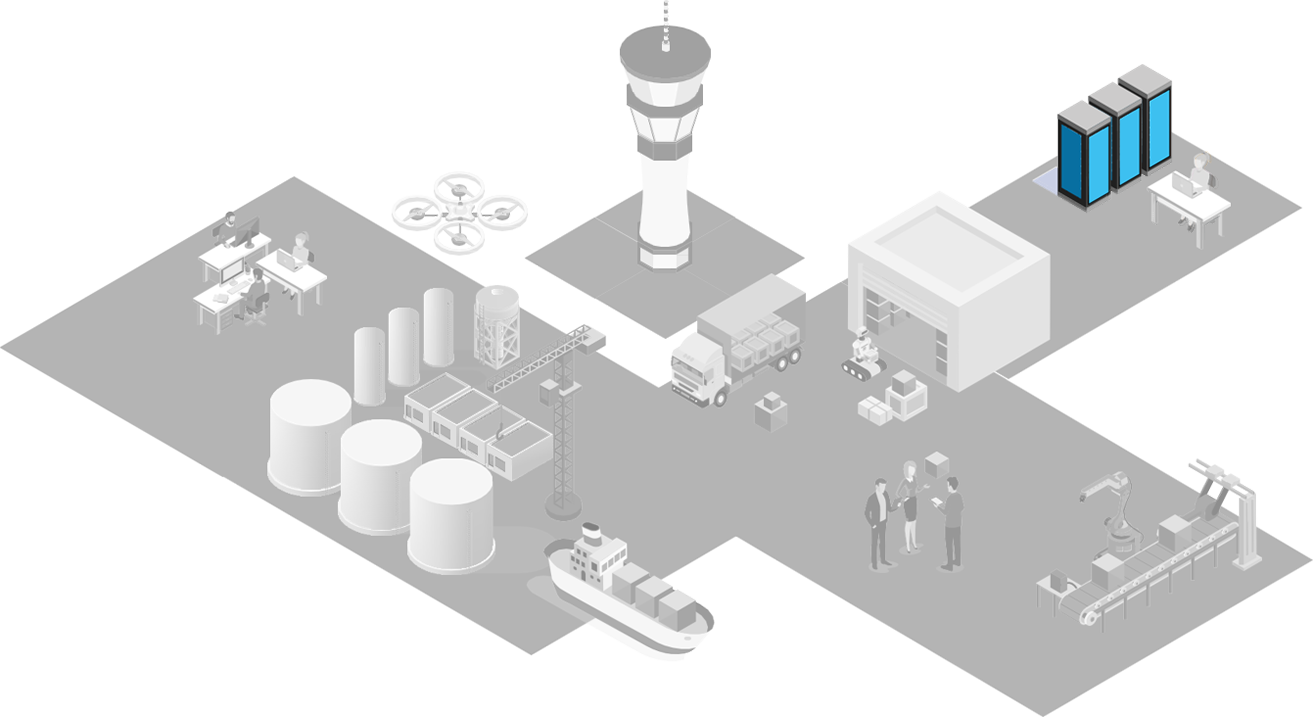

Both underpin our evolution to what we’re calling “The Smart Factory” -- our manufacturing plants reimagined with digital technologies and applications.

Using advanced analytics, and smartphone applications, we’ve set a goal to monitor over 7,000 pieces of equipment with digital tools. This approach gives us the capability to predict the likelihood of failures in our plants far in advance and accurately, or avoid machine breakdowns altogether. The result: less unplanned downtime and lower maintenance costs.

With new laser-based sensors and smartly applied advanced analytics, we’re leveraging the information we gather in our plants. In this data, we find patterns and helpful connections that allow us to predict quality based on past production. We can also make corrections in our plants quickly, which reduces waste and overall costs and ensures the highest quality chemicals and plastics

At the same time our Digital Center is exploring partnerships with startups to find solutions that address today’s business challenges, we’re also looking within for the next great idea.

Braskem Team Members embody the entrepreneurial spirit, and the company has always been ahead when it comes to investing in innovations. Now we’re launching our own startups that have the potential to reshape the chemicals industry.

Edge Portal is a customer portal where clients can easily order products, analyze their account, and access seamless support.

Load Shark is a freight management platform that connects producers and shippers to optimize delivery to clients.

Love Green is a mobile app that encourages recycling and can strengthen the sustainability of the plastics business.

New technology is exciting, but we recognize that people are the key to Braskem’s successful digital transformation. All Team Members will have opportunities to get involved in digital initiatives. We are creating a workplace where they can focus on high-value, strategic work, and be inspired to enhance our client services.

With an Agile mindset, we’re committed to every Team Member having the tools necessary to adapt, grow, and innovate. Our Digital Center is dedicated to making sure everyone at Braskem acquires digital skills, through company-wide training and tangible hands-on experiences.