Braskem

-

English

- Languages

- Portuguese

- English

- Spanish

- Worldwide Sites

- United States

- Mexico

- Europe & Asia

Drag to

view the full map

From the beginning of our operations in 2002, we have been committed to aligning our business strategy with the goal to improve people’s lives based on sustainable solutions from chemicals and plastics.

With a focus on further strengthening our initiatives for sustainable development, we have made public our position concerning the Circular Economy, a document where we define priority actions to expand and promote recycling and the reuse of plastic waste. This commitment also covers further investments in new resins from renewable sources, a goal intended to expand the portfolio that today includes green plastic I’m greentm and supports new technologies, business models, development of the recycling chain and consumer engagement actions.

In January 2019, we teamed up with a group of 30 major companies to help put an end to improper disposal of plastic waste into the environment. Called Alliance to End Plastic Waste, the purpose of the program is to invest up to US$ 1.5 billion (R$ 5.5 billion) over the next five years in projects and new technologies related to this topic.

The organization is not for profit and gathers the entire plastics value chain: companies that produce, use, sell, process, collect and recycle this material.

Our business strategy is align with 10 macro goals defined for conclusion in 2020 and linked to the 17 UN Sustainable Development Goals (SDG). The Braskem Board of Directors regularly monitors the results.

We reviewed the I’m green™ brand, which now offers renewable, recycled and renewable-recycled products. In 2019, a total of 1,651 tons of post-consumer resin were produced and sold, representing 8.2% of the target for 2020. The Chemical Recycling Squad carried out some trials with product from the chemical recycling of post-consumer plastics produced by technology companies partners.

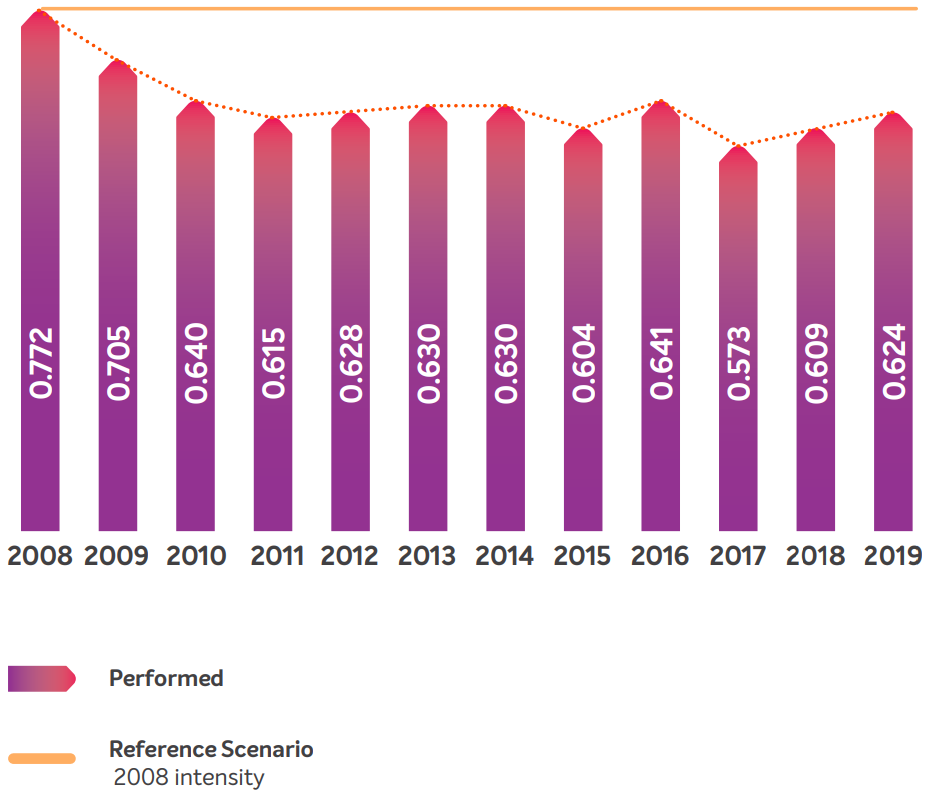

In the period between 2008 and 2019, Braskem’s GHG emissions intensity decreased by 19%, reaching 0.624 tco2e/t, very close to the target established for 2020, of 0.600 tco2e/t. The accumulated avoided rates are equivalent to the carbon stock of an area of approximately 2,500 hectares of Atlantic Forest.

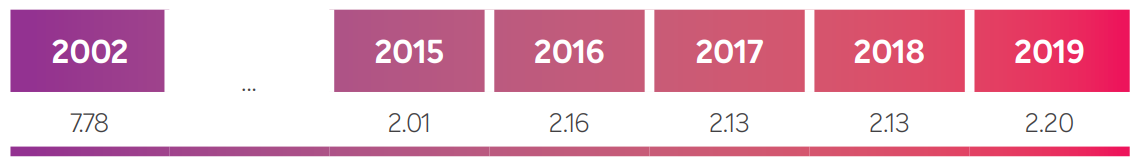

Our water consumption index increased from 4.14 to 4.31 in the period between 2002 and 2019, representing an aggregate negative index of around 4%. Even so, Braskem’s water consumption index is about six times better than the average for the global chemical industry (base: ICCA). The percentage of water reused grew from 18.5 to 25.3 between 2011 and 2019, representing an aggregate improvement of about 37%. The liquid effluent generation index decreased from 1.94 to 1.31 in the period between 2002 and 2019, representing an aggregate improvement of about 32%.

Through strategic actions that focus on respecting values, such as ethics, integrity and transparency, we work to guarantee Braskem’s competitiveness and reputation, and ensure our contribution to economic growth, innovation, eradication of poverty, responsible consumption, among many other topics.

• Completion of the independent monitoring process carried out by the Federal Prosecutors Office (MPF), the US Department of Justice (doj) and the Securities and Exchange Commission (SEC)

• Signature of leniency agreement with the Federal Attorney Office (AGU) and the Federal Comptroller Office (CGU)

• Implementation of the Due Diligence process for Customers (KYC)

• Completion of the implementation of the Compliance Program with the implementation of 100% of the 161 scheduled actions.

• Compliance team composed of 49 Team Members, divided into corporate and regional teams

• Evolution in the evaluation of the ETHOS* Institute’s health indicators, with a score of 9.3 in cycle 18/19

• Approval of the Privacy Policy and Protection of Personal Data

• Achieved the ABERJE Communication Award (regional and national)

• New Courtesy Training

Free cash

generation:

R$ 3 billion

EBITDA:

R$ 5.9 billion

• 3.4 million tons of resins.

• Main chemicals: 2.8 million tons

• Resin exports totaled 1.4 million tons, and exports of the main chemicals, 628,000 tons, up 8% and 10% from 2018, respectively

1.9 million tons

813 million tons

In 2019 we continued to build the new polypropylene plant in the United States - the sixth PP industrial unit in the country. At the end of the year, nearly 85% of the plant - located in La Porte, Texas - had been completed and production is scheduled to start in 2020. With a total investment of US$ 675 million, this will be the largest PP unit and the one with greatest energy efficiency in North America, with an installed production capacity of 450,000 tons per year.

In addition, we announced the completion of the Idesa Petrochemical Plant, in Veracruz, Mexico. The US$ 5.2 billion project increased our resin production by 1.05 million tons, reaching 8.7 million tons of global production capacity.

Another important point of the year was the increase in the acquisition of naphtha via Braskem BV, proving our continuous effort to diversify our Supplier network, increasing the share of natural gas in our raw material matrix.

For us, innovation is directly associated with the development of solutions, products and processes that cause increasingly better environmental impacts and meet the needs of Customers and consumers.

This ambition is connected with at least three of our macro-goals: development of solutions, renewable resources and post-consumption, and converges with our positioning within the circular economy and supports our initiatives in connection with the seven priority sdgs defined by the Company.

We constantly invest in training people, research, infrastructure and strategic partnerships.

2

2

Technology and Innovation Centers, in Triunfo (Brazil) and Pittsburgh (USA)

513

513

Clients received support from the Technology and Innovation Center in Brazil (over 50,000 analyses carried out)

57

57

Customers received support from the Technology Center in the United States (close to 16,000 analyses)

2

2

Technical centers for polymers, one in Wesseling (Germany) and one in Coatzacoalcos (Mexico).

1

1

Process technology development center, in Mauá (Brazil)

As a people-oriented company, we constantly seek to develop the potential of all Team Members, in addition to devising strategies to improve the work environment, creating opportunities for people to grow professionally and personally. Throughout 2019, we put in place several Integration, Training and Development programs, in addition to initiatives to prepare and train Leaders.

Diversity & Inclusion issues were considered on all project fronts and we encourage the creation of a digital mindset in all deliverables in the People & Organization area.

Within our Value Proposition called beux, which presents new possibilities for the development and learning of Team Members and their workplace experience, we finalized the new layout of the five floors of the corporate office in São Paulo (SP) and we opened a lounge area for Team Members at the Camaçari plant (BA).

In 2019, we celebrated five years of our Diversity and Inclusion Program.

All of our operations have actions to engage with the Community. Our Private Social Investment (ISP)2 strategy is driven by three priority causes: consumption, sustainable post-consumption and circular economy; sustainable innovation and entrepreneurship; and local development.

In order to be included in our isps, projects must fulfill three important objectives: expand the positive social and environmental impact, promote the company as a provider of sustainable solutions and establish trusting relationships with communities and other stakeholders.

Throughout 2019, more than 530,000 people were directly benefited in the various areas where we operate.

The purpose of our global volunteering program is to generate a positive social and environmental impact on the communities located around Braskem’s operations.

Held in Mexico, the purpose of this program is to encourage recycling and teach the community to sort plastic waste. The materials can be exchanged for currencies called plastipesos and, with them, it is possible to buy cleaning products and food for an amount subsidized by Braskem.

In 2019, the collection benefited 1,500 families and reached 49.6 tons, a result 75% higher than the previous year.

The project aims to promote social inclusion and socioeconomic development of people who work in the collection and sorting of recyclable materials and cooperated.

In 2019, Ser + served 43 screening units and cooperatives, providing a 29% increase in the monthly income of the beneficiaries of the project, more than double the stipulated target.

In the U.S., we support the Science Leadership Academy (SLA) in the science, technology, engineering and mathematics education program. The project allows freshmen- or sophomore SLA students to do an internship at our plant in Marcus Hook. In addition, through the Capstone Acceleration Program, our Team Members act as mentors to senior students in preparing their undergraduate thesis.

We work hand in hand with our Clients to build and foster a more sustainable future for our entire value chain. Acting in an integrated manner, we are able to think and create efficient products and solutions, considering the commercial demands while we follow and strengthen the principles of the Circular Economy.

Our outstanding initiatives are:

We have entered into partnerships with several customers to develop more sustainable products, such as renewable products that expand and facilitate recycling and reuse of plastic packaging.

In addition, we developed actions and solutions to value post-consumer plastic waste and the recycling chain as a way to mitigate environmental and social risks. To this end, we entered into partnerships with Customers, recyclers, cooperatives and consumer brand companies.

Through our partnership with the Brazilian Plastics Industry Association (ABIPLAST) we promote initiatives that encourage the export of transformed products.

This family of products offers eco-efficient resins that help reduce energy consumption during the production process and the weight of final products, in addition to increasing productivity, which contributes to reducing production costs and environmental impacts.

We have in place a decentralized management structure, with different areas working on spend analysis, evaluating the quality of products and services and adherence to the Third Party Code of Conduct. The Code is based on widely accepted documents ranging from the UN Universal Declaration of Human Rights to the procedures recommended by the International Labor Organization (ILO) and the laws and regulations of countries where we operate.

In April 2019, the Procurement area, supported by Braskem’s Sustainable Development area, held the first event to recognize suppliers with best performance in management of water resources and climate change issues. The criterion for recognizing suppliers was the performance at the 2018 CDP: everyone was on the “A List,” i.e., they were all companies with excellence in managing greenhouse gas emissions, water consumption and use of forests.

The Logistics area works alongside the Health, Safety and Environment (HSE) team to ensure that all social and environmental requirements critical to operations are met through the hiring of transportation, terminals and other logistics services.

In all of our processes and in all relationships with stakeholders, we adopt attitudes and strategies of responsibility, integrity and transparency.

To this end, we promote open dialogues and are guided by a commitment to ethical management. This is no different from our relationship with governments.

We ended 2019, and once again, registered zero fatal accidents. This is the result of our efforts to find ever better ways and solutions in terms of safety, efficiency and sustainability in our operations.

Throughout the year, we work every day to create opportunities and positive results for Braskem employees, Communities near our plants and for the environment. One of the highlights was the final implementation and training of Intelius, our new Integrated Management System.

The system meets all the HES, Quality and Industrial Excellence requirements, providing guidelines and reporting on best international practices on the necessary actions in the industrial areas.

In addition to all the actions carried out within our units, we advocate the responsible use of water and innovative conservation solutions. The main initiatives are:

Investments in HSE improvements totalized R$ 203.5 million, about 40% higher than 2018.

Our percentage of water reused grew from 18.5 to 25.3 between 2011 and 2019.

Braskem and Siemens stablished a partnership to increase energy efficiency in São Paulo, ABC, through a cracker modernization project. This initiative will result in an improvement in Braskem´s sustainability indicators, in addition to higher efficiency in the production process.

Concluded the installation of 1 mwp out of 5mwp of the floating solar panels farm project, located in the Sobradinho´s hydroelectric plant, controlled by CHESF in Bahia. Project developed in partnership between Sunlution and UNIPAC group.

Start of the solar power plant operation in Bahia, with a capacity of 97 Wp, installed in an area of 2500 m2, supplying 27% of our Salvador´s office demand.

*Total production excludes internal transfers of finished product

For the coming years, our efforts will be focused on mapping an additional reduction potential of 1 million tco2e.

• Since 2016, Braskem has been classified as a leading company in the CDP Climate.

• For the ninth consecutive year, Braskem obtained the gold classification in the Brazilian GHG Protocol Program.

For the third consecutive year, we have been recognized as one of the companies listed on the “a list” on water issues at cdp water, which selects the best publicly traded companies in the world in relation to management of water consumption.

In 2018, we were a Brazilian highlight in the CDP Supply Chain ranking. For the first time, we were included in the “Water A” Supplier List and for the second consecutive year, the “Climate A” Supplier List.

Check the report from previous years: