Our purpose is to improve people's lives by creating sustainable solutions through chemistry and plastic. For this, we are present in essential items for everyday needs, in different market segments.

Braskem’s segments of Operation

Learn about the market segments in which we operate and the various applications of the raw materials that we produce that are essential to people’s daily lives.

Consumer Goods

Braskem solutions in resins and chemical special products are present in our day-to-day items for movements, storage and medical articles as well as domestic, industrial and furniture accessories.

Plastic packaging is practical and represents a high functionality as the physical barrier that preserves food from humidity, dirt, air, light, and unwanted microorganisms, ensuring product safety and quality. We can find plastic in several other types of packaging such as hygiene and cleaning products, pet food, cosmetics, jars and lids, providing benefits such as protection, ease of transport, storage, among others. Properly disposed of, plastic packaging is reused and recycled.

Applications

With the purpose of making people’s lives better and taking into consideration the main challenges of the modern world, Braskem is highly committed on creating innovative and sustainable solutions through chemicals and plastics.

We are developing the next generation of performance polypropylene that exploit recent advances in catalyst and process technology, combined with polymer science and engineering innovation.

Braskem’s polypropylene designed for film applications allow producers to enhance their current film formulations. This evolution aims to provide a greater balance of processability and performance, which adds versatility and flexibility. Benefits from the proven performance that helps our clients add value to a wide range of innovative downstream solutions include:

- Improved melt strength enabling down gauging

- Low gel level to guarantee superior film quality

- Balanced stiffness and impact properties

- Outstanding optical properties for the different application needs

- Resins suitable for food contact applications downstream formulation development

Our products are used in:

- Primary and secondary food packaging

- Industrial packaging

- Hygienic films

The versatility of polypropylene imparts a range of unique characteristics to products, combining durability, comfort and convenience in a variety of textile applications:

- Masks

- Surgical gowns

- Diapers

- Wipes

Braskem offers a wide range of products for injection molding applications that features good processing, excellent mechanical and optical properties and high flexibility for innovative designs.

Benefits in TWIM applications are reduced source consumption, shorter cycle times, high clarity, and good organoleptics.

In addition, Thermoformed packaging plays a vital role in our daily lives, protecting foods such as dairy, shelf stable, and frozen products.

- Thin wall injected packaging

- Blow moulded bottles

- Thermoformed packaging

-

Caps & Closures

- Food Applications – Carbonated Soft Drinks (CSD), Beverages, Mineral water, Food

- Non-Food applications – Home care, Industrial use, Personal Care

Braskem offers a wide range of products for houseware applications that provides good processing, excellent mechanical and optical properties and high flexibility for innovative designs.

Our products feature high melt flow rates, which provide:

- Faster cycle times

- Greater flexibility in product design

- Balanced stiffness and impact properties

In addition, transparent products are better suited for food storage containers and organizers. Braskem’s polypropylene also provides good mechanical properties, ensuring the useful life of finished items.

- Household – Home storage, Food storage, Kitchen utensils, Trash bins

- Garden – Furniture, Flowerpots, WPC decks

- Child ware – Child Chairs, Toys, Organization

Healthcare

This is Medcol, the Braskem solution that builds enduring, reliable bonds in the healthcare industry, co-creating unique customized solutions that care for people’s lives.

Consistent

- No change of formulation

- 2 year notification of change period

Controlled

- Healthcare Protocol

- Special cleaning, production and storage instructions

- Change Control Management

Compliant

- Testing after EP 3.1.6, USP 661.1, USP 87, USP 88, ISO 10993*

- Open for customer audits

* total scope depends on grade

Applications

Film applications require high quality standards for polypropylene resins. Flexibility in the film design is important to cover a wide range of applications from transparent bags for IV solutions to blister packaging

Safety and user friendliness are main drivers for PP bottles and ampoules. Polypropylene is safe for autoclave sterilization at high temperatures, the preferred sterilization method for medical plastics.

Water Management

Braskem is your experienced and reliable partner in products for water management. We supply selected products to meet your requirements. Our portfolio range includes Homopolymer and Heterophasic Copolymer Polypropylene and High Density Polyethylene. We constantly strive to advance solutions to enhance our portfolio and to develop new products in cooperation with you.

Our responsibility

We understand our responsibility as a company. This is why we assume the role of agents of transformation in all sectors and places in which we operate. Braskem works with goals that consider the 3 dimensions of sustainable development: economic, social and environmental. These goals are part of our Global Sustainable Development Strategy and are aligned with the UN Sustainable Development Goals.

Among dozens of initiatives, we partner with companies and people involved in the plastic lifecycle to strengthen recycling and proper disposal. Thus, we transpose technical and logistical barriers to ensure proper re-insertion into the quality and quantity recycled materials chain. We also seek to promote human rights and equality in our value chain, contributing to the development of the local communities where we operate, always putting people and the environment first.

Braskem chemical products are present from the beginning to the end of the production chain - and we value each step. We develop partnerships with our customers in various segments that add value and drive the arteries of the economy, always focusing on innovation and sustainability. We create tangible solutions to make the world a better place.

Find out more about our commitmentsApplications

Injection molded fitting with a good creep and temperature resistance.

Our PP extrusion grades are designed to fullfill your requirements for non-pressure underground drainage and sewerage pipes. Furthermore, we offer products for cables and multilayer pipe systems.PP provides a very high stiffness and impact as well as a good chemical resistance compared to PVC pipes.

- Currugated pipes

- Rainwater collectors

- Conduits

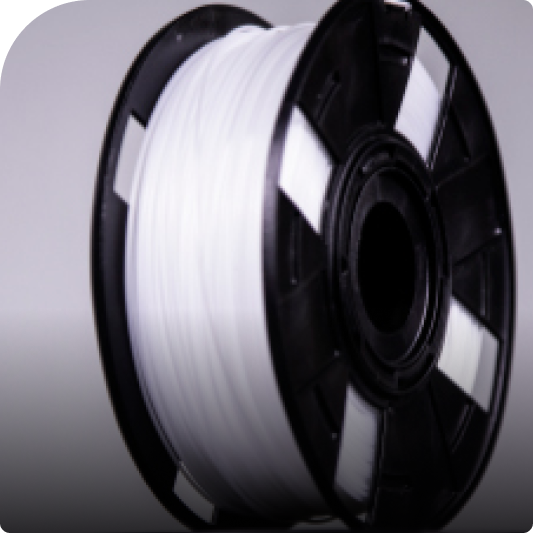

3D Printing

As one of the world’s largest producers of polyolefins, it made sense for Braskem to enter the world of 3D Printing. Braskem offers solutions for many of the primary 3D printing technologies such as Fused Filament Fabrication (FFF), Selective Laser Sintering (SLS), and High-speed Pellet Extrusion.

Through our decades of expertise in materials science and product development, our state-of-the art 3D printing labs, and our strategic partnerships with industry leaders, we are committed to delivering new and innovative products to the market.

Regardless if you are a start-up, university, equipment manufacturer, converter, compounder, or brand owner, reach out to us today to learn more about our product development pipeline and how we can collaborate with you on your next 3D printed solution.

Applications

Braskem filaments are designed for the end user. They are intended for the production of cutting and drilling jigs, as well as accessory performance improvements, prototyping and testing to reduce weight and optimize geometries, spare parts and the design of containers with excellent tightness, lighter weight and with living hinges.

In a strategic partnership with Advanced Laser Materials (ALM), Braskem developed its first line of powders for selective laser sintering (SLS). Through this collaboration, Braskem can offer solutions that can be employed by a wide variety of market segments, such as automobile, aerospace, packaging, and consumer products.

Braskem 3D printing pellets are specially developed for direct use in processes with granulated raw materials. Our unique formulations improve printability and overall flow to ensure the highest quality prints.

Automotive

Since the 1960s, plastic has become part of the automotive industry in a significant way, and during recent decades has yielded new benefits, providing for a huge reduction in weight, less fuel consumption and increased design flexibility, with more rounded and bolder lines in vehicle models.

Currently vehicles have on average 50 kilos of parts and accessories made of plastic within the interior, exterior and even next to the engine, replacing around 350 kg of steel.

Braskem’s broad polypropylene (PP) portfolio meets the needs of today’s sophisticated automotive and compounding applications. Benefits from the proven performance that helps our customers add value to a wide range of innovative downstream solutions include:

- Reduced wall thickness enables using less raw material in achieving light weighting solutions that lower transportation costs, improve fuel economy, and reduce emissions.

- Unique balance of stiffness, toughness, and flowability offer exceptional competitive advantages for multiple end users.

- Joint technology and innovation platforms that enable our clients to meet and exceed stringent market demands.

Applications

PP fiber reinforced compounds offer a high degree of freedom in design allied with a reduction in weight in relation to the use of metal. The Braskem high melt flow portfolio is the perfect fit for this market.

In addition to withstanding the most diverse of weather conditions, nowadays we can see the most varied formats in items with straightforward design and function, such as rear-view mirrors and door handles.

Applications in automobile compounds (polypropylene) highly innovation based. Results are observed primarily in terms of performance and emissions within vehicle interiors.

Aggregating quality and cost, today we see lots of compound parts when opening the hood of any vehicle. Compounds enable parts to be designed with increasingly complex geometries.

High melt flow for fast processing combined with high impact and heat stabilization results in high performance PP grades for classic car batteries.

The home appliance segment is characterized by product innovation. Applications demand high mechanical strength, processability, and esthetic qualities. Polypropylene resins meet these requirements by delivering design flexibility, brightness, excellent performance, high productivity, competitiveness, and sustainability over substitutes.

In addition to the grades already established in this segment, Braskem is constantly developing new resins with a unique balance of properties to allow its clients that produce household appliances to innovate and respond to trends in the sector. We also have a line of post-consumer resins, which aims to meet the requirements of the applications and bring a sustainable appeal to products.

Braskem Global

Braskem Global

Braskem Idesa

Braskem Idesa

Braskem USA

Braskem USA

Braskem Europe

Braskem Europe