Resolving the question of Land Use in Plastics Production

Braskem's Henri Colens, External Affairs Leader Europe & Asia, ponders how using agricultural biomass could support a sustainable plastics economy

It's going to be a hot day in São Paulo. In the early morning, a line of joggers stretches out along the edges of Ibirapuera Park, as the road curves around a small lake. Some of these people may not know it, but there's a footprint revolution happening right under the soles of their feet.

Not only are some of the runners wearing sneakers that are lighter and more comfortable, but they're carbon neutral too. That's because some of the leading sportswear brands have woken up to the power of the sun, and the miracle of photosynthesis - they are increasingly switching to plant-based materials.

The daily miracle is happening some 500 kilometers west of São Paulo, on the outskirts of a town called Presidente Prudente. As the sun keeps rising, hundreds of kilometres of farmland stretch out towards the horizon, waiting to be cultivated, harvested and processed. This is sugarcane country, and the epicenter of an industry which has become a key part of Brazil's economy, and its fight against climate change.

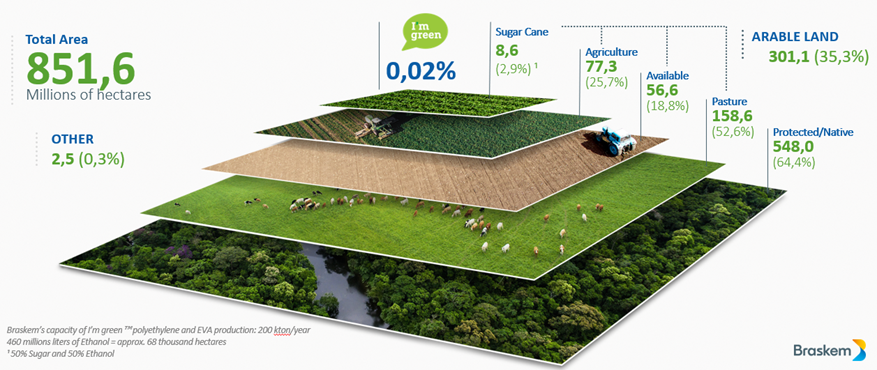

First, some interesting facts about Brazil. One of the largest countries in the world, it has a total area of 851 million hectares, larger than the whole European Union and larger than the continuous USA (excluding Alaska and Hawaii). 548 million hectares (64% of its territory) are protected land leaving 301 million hectares for economic activity of which 52.6% is used for raising cattle, 18.8% remains idle and 28.5% is used for agriculture.

Brazil has been growing sugarcane since the 16th century and it now leads the world in innovative technology to plant, manage and harvest it. Sugarcane occupies around 3% of the arable land and is responsible for the production of 665 million tons of sugar and 34 billion litters of ethanol. Brazil produces 25% of the world's sugar and ethanol in an industry that brings in around 45 billion USD every year, employing more than 1 million people.

Whilst a significant proportion of the sugar usually ends up on our plates or in our soft drinks, this bio-ethanol has become a hugely important resource for the fuel and chemical industry. Sugarcane supplies around 18% of the Brazilian energy matrix. But in recent years, it's going into the plastics industry too. In 2010 Braskem launched its I'm greenTM polyethylene. More recently we developed I'm greenTM EVA, a sustainable foam rubber substitute, which is, you guessed it, ready-made for the footwear industry.

So, back to those runners, now heading home after working up a sweat. I wonder whether they think about what it really means to transition from a fossil-based plastic to a plant-based one. I suspect many of them feel it's a positive choice that they've made, an investment in a climate-friendly innovation. But in truth it's perhaps a more complex issue than many realise, not least because of a concept known technically as "iLUC", or indirect Land Use Change. In the early 2010s, researchers began to focus on the unintended consequences of expanding use of cropland to produce biofuels. And what they found ignited a debate about whether we should subsidise the use of arable crops at all.

At the heart of the matter is the fact that, as countries began to offer subsidies on the production of biofuels it meant higher or guaranteed prices for certain crops, which led to farmers clearing land or replacing certain food crops in order to secure a better source of income. More worryingly, researchers found instances when natural lands, such as forests and grasslands were replaced, leading to a variety of impacts: biodiversity loss, increases in GHG emissions, eutrophication and depletion of soil carbon stock.

But experts believe that, while iLUC is an important factor, and that sustainability criteria are essential in assessing the impact and monitoring the development of such materials, the last 10 years have created enough understanding of the issue that it has become easier to resolve. Whilst determining what causes iLUC and how it can be separated from direct Land Use Change (dLUC) is not easy, policymakers have laid down guidelines (and certifiers have applied rules) which manage the problem. For example, the EU expects that any expansion or increased demand for biomass should come from land that is already cultivated. In the case of sugarcane in Brazil, such expansion is predominantly coming from degraded pasture land, due to self-imposed industry rules reinforced by national legislation. Braskem has also put in place a third layer of protection by developing, together with Proforest, a Sustainable Ethanol Supply Platform with requirements that cover not only land use but also worker's welfare, agricultural best practices such as reduced fertilizer and pesticide use, environmental management systems and relationship with the local communities. Our suppliers are audited at least once every two years by an independent third party to ensure adherence to this platform.

The industry assessment of potential areas for production expansion shows that land is available to supply the production of 205 billion litters of ethanol for export in 2025, without entering sensitive biomes such as the Amazon, Pantanal and Atlantic forest. A recent study considered the establishment of environmental reserves in 20% of the planted area and considered that areas of forest, indigenous reserves, parks, etc., are not used for the expansion of sugarcane production. Another aspect to be mentioned is that the cultivation of sugarcane provides soil recovery, in comparison with the planting of other crops.

And the related issue of competition with food is lessened by the fact that Brazilian sugarcane mills co-produce both sugar and bio-ethanol. In modern mills, the first press squeezes out the sugar juice that goes for sugar production, subsequent presses with hot water extracts residual sugars that blended to molasses go to fermentation tanks where a kind of wine is produced. In the distillery where the ethanol is produced, there is a high quantity of vinasse generated. This residue that is rich in nutrients is either applied directly to the field as a source of water and nutrients, or is used to produce biogas and compost. The leftover biomass from the presses is used as biofuel in a power plant that supplies all the heat and electricity the mills require, with the excess being exported to the grid.

The consumption of ethanol for the production of 200 kt/y of I'm greenTM bio-based Polyethylene & EVA represents about 1.8% of the total production of ethanol, or 0.02% of Brazil's arable land. The use of land for the production of chemicals from renewable sources, even in a very optimistic scenario should continue representing a small percentage of the total land available. The global polyethylene consumption of 100 million metric tons would require around 35 million ha against a projected available land in Brazil of 176 million ha.

On top of all these arguments, in the state of São Paulo, where 60% of the country's sugarcane is planted, crop rotation with leguminous vegetables is a common practice that helps fix nitrogen in the soil. Hence 15% to 20% of sugarcane producing areas are also used for the cultivation of soybean, beans and peanuts, supplying the food market.

This all means that the runners of São Paulo, and indeed around the world, now have access to a greater choice of sustainable footwear. Whether it's the use of Ocean-recovered plastics, or sugarcane-based EVA, more and more companies are offering products that have a reduced or negative environmental impact.

The transition to non-fossil, renewable alternatives must be carefully managed, but the use of land to grow crops to make chemicals and plastics can be a sustainable way to decrease emissions and wean ourselves of finite resources.

News

More news

Braskem and Katoen Natie Partner on a Logistics Project in Singapore

![[JP] Braskem and Katoen Natie Partner on a Logistics Project in Singapore](/portal/europe/arquivos/listas/15762/capa.jpg?v=1)

[JP] Braskem and Katoen Natie Partner on a Logistics Project in Singapore

From Air to Plastics: Norsk e-Fuel and Braskem Partner to turn Captured Carbon into Long-Lasting Products

Accelerating the Transition to Renewables: Braskem's I'm greenTM bio-based Supports TE Connectivity's Sustainable Heat Shrink Tubing Innovation

With Braskem's I'm greenTM bio-based Polyethylene, Balsam Hill Made the World's First Plant-Based Plastic Christmas Trees

Braskem Global

Braskem Global

Braskem Idesa

Braskem Idesa

Braskem USA

Braskem USA

Braskem Europe

Braskem Europe